the Tantalum-Niobium International Study Center (T.I.C.) : Production of raw materials : About Tantalum

An international, non-profit association founded in 1974 under Belgian law.

- Metals: Tantalum (Ta)

- Read 925 Times

- Metals: Tantalum (Ta)

- Industries : ALL, Miners

Production of raw materials

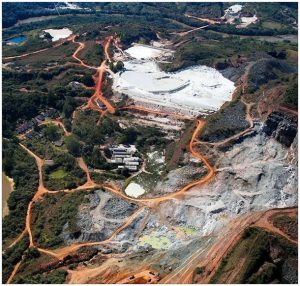

Extraction or production of tantalum raw materials of all kinds is widespread, whether by primary industrial mining, artisanal mining, as a secondary mineral or as a byproduct. Brazil is currently the major producer. Significant quantities are also produced in China, the DR Congo, Russia and Rwanda. Additional quantities are produced, some intermittently or at a low level, in Australia, Burundi, France, Malaysia, Mozambique, Namibia, Nigeria, Thailand and Zimbabwe.

In the years leading up to 2008 the main mining operations were in Australia, Brazil, Canada, Ethiopia and Mozambique. Following the world economic crisis the main mining operations in Australia, Canada and Mozambique ceased production. Since then, there has been intermittent production in Mozambique, while Australian production resumed at a reduced level for a seven month period in 2011. In 2012, Ethiopian production was stopped due to transport difficulties preventing export.

In terms of resources, whether currently exploited or not, in addition to Australia and Brazil there are other significant resources in China, the DRC, Ethiopia, Mozambique, Nigeria, Russia and Rwanda. Tantalum is also produced in Brazil, Malaysia and Thailand as ‘tin slag’, a by-product of tin mining and smelting. Tantalum raw materials are also being explored in Canada, Colombia, Egypt, Madagascar, Namibia, Saudi Arabia, Sierra Leone, South Africa, Tanzania, Venezuela and Zimbabwe.

Mostly Likely Resource Base

| Source | Mlb | Percentage |

|---|---|---|

| South America | 285 | 40% |

| Australia | 145 | 21% |

| China and Southeast Asia | 73 | 10% |

| Russia and Middle East | 69 | 10% |

| Central Africa | 63 | 9% |

| Other Africa | 47 | 7% |

| North America | 12 | 2% |

| Europe | 5 | 1% |

| Total | 698 |

Tantalum minerals with over 70 different chemical compositions have been identified. Those of greatest economic importance are tantalite, microlite,and wodginite; however, it is common practice to name any tantalum-containing mineral concentrate as ‘tantalite’ primarily because it will be processed for the tantalum values and is sold on that basis.The minerals are concentrated by physical means at or near the mine site to increase the percentage of tantalum oxide and niobium oxide by weight.

The concentrates are transported to the processors’ works for chemical processing. Tantalum mineral concentrates may contain from two to more than five different tantalum-bearing minerals from the same mining area.The sale of tantalum mineral concentrates is based on a certified analysis for the tantalum oxide (Ta2O5) they contain,with a typical range from 20% to 60% depending on the mine source.

The single largest operating tantalum mine is the Mibra operation of Companhia Industrial Fluminense in Nazareno.This mine has the capacity to produce 220 tonnes Ta205 per year which equates to approximately 15% of current global primary production,although the latter are at historically relatively low levels. At 2007-2008 levels the Mibra mine accounted for 5-10% of global primary production. Additional significant operating mines are the Lovozero mine in Russia,the Yichun mine in China and the Pitinga mine also in Brazil. Significant but closed mines include the Greenbushes and Wodgina mines both in Western Australia, the Tanco mine in Manitoba Canada,and the Kenticha mine (Ethiopia Mineral Development Enterprise) in Ethiopia.

Significant quantities are also obtained from alluvial and soft rock deposits by artisanal mining, primarily in centralAfrica. Individual mines are small and rely on manual tools and labour. Mining investment has been curtailed for many years, whether due to lack of funds or whether due to political instability and associated risk in e.g. the Democratic Republic of Congo. As a result there are no known or measured deposits associated with artisanal production.

In Brazil, Malaysia and Thailand,the tin industry provides tantalum as a component of the tin slag by-product, that arises from the smelting of cassiterite ore concentrates for tin production. Struverite concentrates (a Ti-Nb-Ta mineral) have historically also been available from northern Malaysia containing 9-12% tantalum oxide.

Scrap recycling generated within the various segments of the tantalum industry has for a long time accounted for about 20% of the total input each year, while in 2012 this increased to some 30%.

In summary, the global supply up until 2008 and as of 2012 looked as below,with considerable fluctuation in the proportions between 2008 and 2012.

| Source | Percentage 2008 | Percentage 2012 |

|---|---|---|

| Primary concentrates | 60% | 40% |

| Secondary concentrates | 10% | 10% |

| Tin slag | 10% | 20% |

| Scrap recycling, synthetic concentrates | 20% | 30% |

- Author: Tantalum-Niobium International Study Center (T.I.C.)

- Published Date: 10/03/2025

- The T.I.C. was established in response to concerns within the tantalum industry regarding the lack of useful information on tantalum source materials. The initial purpose of the T.I.C. was to spread information about tantalum and to promote the common interest and welfare of the producers, especially with public and private authorities, organisations and agencies. Since its foundation, the T.I.C. has grown to encompass niobium and all stages of the tantalum/niobium supply chains.

Advancing sustainability, technology, and industry collaboration since 1974.

Driving Global Innovation in Tantalum and Niobium

Connecting global innovators in tantalum and niobium, driving advancements from raw materials to cutting-edge applications.

- Supporting over 90 members across 30 countries.

- Promoting cutting-edge research and development.

- Facilitating a global network of professionals.